Electric button to adjust the round steel tube polishing machine

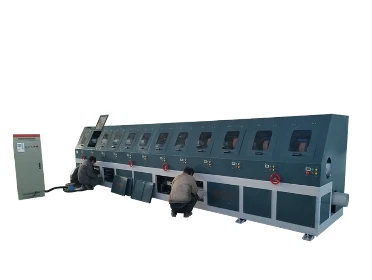

The horizontal type of multi-station round pipe polishing machine mainly processes shorter workpieces with smaller diameters. The operation is simple, the speed is stepless speed regulation drive, suitable for polishing different requirements of the change and adjust the transmission speed.

New automatic round pipe rust removal and polishing machine

The multi-station round tube polishing machine adopts a separate completely closed case, and the parts that often need to be adjusted are designed as trap doors, which are convenient to change and repair and beautiful to open outside. The whole flexible and simple host conveying system bloating electromagnetic speed regulating motor is driven separately, which can complete the required adjustment of various conveying speeds, and easy maintenance.

Wet stainless steel pipe rust polishing machine

Round tube polishing machine is also called centerless polishing machine, centerless circular polishing machine, circular polishing machine, can be divided into a single group of circular tube polishing machine and multi-station circular tube polishing machine.

Multi-grinding head SS round pipe rust removal polishing machine

Preparatory work

1.1 Check whether the machine is placed on a flat workbench; Whether the parts are complete, whether the fasteners are loose, do a good job of cleaning.

1.2 Connect the water inlet pipe and the drainage pipe, and pay attention to the drainage place should be lower than the height of the drainage port, otherwise it will affect the discharge of waste liquid.

1.3 Check whether the power supply meets the working requirements, and whether the connection and grounding of each line are safe and reliable.

Multi-grinding head SS round pipe rust removal polishing machine

And according to the different materials and polishing requirements of the workpiece, flexible selection of abrasive cloth page wheel, hemp wheel, cloth wheel, nylon wheel and other polishing tools for polishing the workpiece. The workpiece support plate is made of wear-resistant material, which does not need to be adjusted frequently.

New SS pipe outer round rust removal polishing machine

Round pipe polishing machine is mainly used in hardware manufacturing, vehicle parts, steel and wood furniture, instrument machinery, standard parts and other industries before and after electroplating rust and polishing, is a good choice for round pipe, round rod, slender shaft polishing.

Protective shell stainless steel tube polishing machine

Protective shell stainless steel tube polishing machine

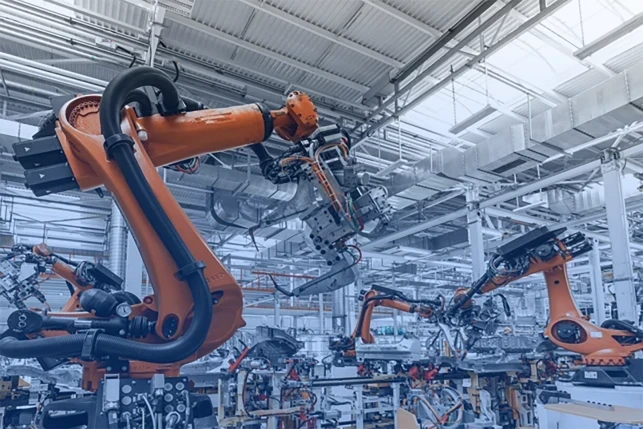

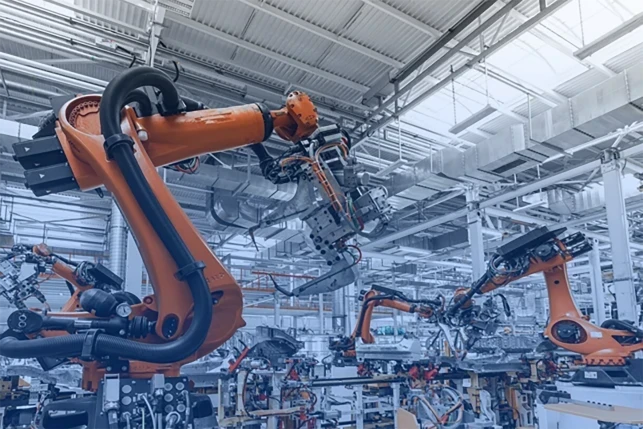

The Multi-Station Horizontal Tube Polishing Machine is widely used in industries that require high-volume and consistent polishing of metal tubes. It is especially suited for stainless steel, aluminum, and copper tubes used in furniture manufacturing, automotive components, architectural structures, and decorative piping. Its multi-head design allows simultaneous polishing of multiple tubes or different sections, greatly enhancing production efficiency and ensuring uniform surface finishes.

With adjustable speed and pressure controls, the machine can achieve various finishes including mirror polish, satin, and matte textures to meet diverse customer requirements. Its robust construction and precise engineering ensure stability and durability during continuous operation. This machine is an essential tool for manufacturers aiming to improve product quality, reduce labor costs, and maintain high productivity in large-scale production environments.